|

|

| A leading offering for corrosion protection and marine growth prevention |

|

| The leading Cathelco® hull corrosion protection systems (ICCP) and marine growth prevention systems (MGPSs) reduce maintenance costs and notably lengthen vessels’ lifecycles. Cathelco® spare parts and onboard services comply with Article 95 of the EU Biocidal Regulation for the use of copper in European waters and every vessel trading in EU waters. |

|

|

We provide a comprehensive range of Cathelco®

MGPS and ICCP solutions

|

| |

- Impressed Current Cathodic Protection System (ICCP)

|

| |

|

|

- Marine Growth Preventive System (MGPS)

|

| |

|

|

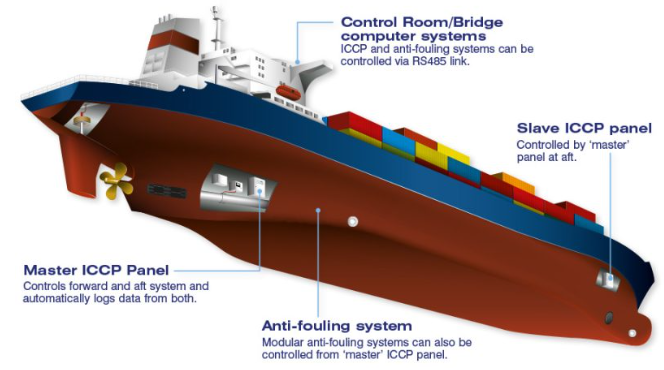

| Impressed Current Cathodic Protection (ICCP) |

|

| What is corrosion protection? |

| Modern hull coatings provide some protection against corrosion, but they are not a complete solution. For this reason, most operators choose to protect their vessels with a purpose-designed impressed current cathodic protection (ICCP) system. Our Cathelco® hull corrosion protection systems have been designed for various vessel types: Commercial and cruise ships, fast ferries with steel or aluminium hulls, naval vessels, fishing vessels and other workboats and luxury yachts. |

|

|

| How corrosion protection system work? |

| Using an arrangement of hull-mounted anodes and reference cells connected to one or more control panels, the system produces a more powerful external current to suppress the natural electro-chemical activity on the wet surface of the hull. This eliminates the formation of aggressive corrosion cells on the plate surfaces, avoiding problems that can exist where dissimilar metals are either combined through welding or brought into proximity by other components such as propellers. |

|

|

| What are the benefits of the system? |

| Our Cathelco® corrosion protection systems are designed to automate the current output while the voltage output is varied. This allows protection levels to be maintained as seawater resistivity alters. In a sacrificial anode system, increases in seawater resistivity can cause a decrease in the anode output, and in turn in the level of protection offered. With an ICCP system, protection does not decrease across the standard range of seawater encountered. An essential feature of our Cathelco ICCP systems is that they constantly monitor the electrical potential at the interface between the seawater and the hull, carefully adjusting the output to the anodes in response. Therefore, the system is much more effective and reliable than a sacrificial anode system, where the level of protection is unknown and impossible to control. |

|

|

| Why choose Cathelco® ICCP technology? |

|

| Effective and reliable |

| Cathelco® ICCP systems constantly monitor the electrical potential at the interface between the seawater and the hull. Therefore, the system is much more effective and reliable than a sacrificial anode system, where the level of protection is unknown and impossible to control. |

|

| Significant savings |

| By installing a Cathelco® C-Shield system, operators can make significant savings in hull maintenance costs and also reduce fuel costs thanks to a smooth hull surface. Furthermore, increased hull integrity safeguards the owner’s investment and increases safety. |

|

| Lifetime warranty |

| Evac has introduced a lifetime warranty for its Cathelco® range of impressed current cathodic protection (ICCP) systems. The lifetime warranty has been driven by the demand from customers for reliable products which deliver optimal performance for longer periods of time. |

|

|

| Marine Growth Prevention System (MGPS) |

|

| What is marine growth prevention? |

Marine growth prevention eliminates the settlement of macro biofouling organisms on the ship’s interior piping systems, thus creating less waste due to the longer lifecycle of the pipes.

Our Cathelco® marine growth prevention systems (MGPSs) for seawater pipework are easy and economical to install, and they can be found on more than 50,000 ships worldwide. Designed to eliminate blockages caused by barnacle and mussel growth in seawater cooling lines, the systems are available for vessels of every size including mini systems for luxury yachts. |

|

| How does marine growth prevention work? |

Marine growth prevention systems (MGPSs), also known as antifouling systems) usually consist of pairs of copper and aluminium anodes, mounted in sea chests or strainers and connected to a control panel. In operation, the copper anode produces ions that are carried by the flow of seawater, creating an environment where barnacles and mussels will not settle or multiply.

By introducing copper ions in very small concentrations, around two parts per billion, the system interrupts the settlement sequence of mussel and barnacle larvae. Instead of adhering to the surface of sea chests, strainers, and pipework, the larvae pass harmlessly through the cooling water system to the discharge point. Without antifouling protection, pipes can become encrusted with organisms, leading to a blockage that reduces the efficiency of the seawater cooling system. |

|

| Compliant with EU biocide regulations |

|

| Why choose Cathelco® products? |

|

| Guaranteed quality |

| Cathelco® marine growth prevention systems (MGPSs) for seawater pipework are easy and economical to install, and they can be found on more than 50,000 ships worldwide. Designed to eliminate blockages caused by barnacle and mussl growth in seawater cooling lines, the systems are available for vessels of every size including mini systems for luxury yachts. |

|

| Compliant with regulation |

| Owners and operators of vessels sailing in European waters must ensure that their marine growth prevention systems comply with the EU Biocides Regulation 528/2012. Cathelco® is one of the few companies listed under Article 95. This makes installing genuine Cathelco® equipment and anodes a safe way to ensure regulatory compliance. |

|

| Life-time warranty |

| In line with the strategic mission of greater sustainability, Evac has introduced a life-time warranty for its Cathelco® range of marine growth prevention (MGPS) systems. The life-time warranty has been driven by the demand from customers for reliable products which deliver optimal performance for longer periods of time. |

|

|

|

|

|

| HEM® and Evac® fresh water generation systems turn seawater into the process, service, and drinking water. The equipment also filters and disinfects the water, adjusts its hardness, and mineralizes fresh water that has been created or stored. We offer seawater desalinators using reverse osmosis (RO), as well as potable water treatment equipment using mineralization and disinfection. |

|

| Why choose Evac® and HEM® fresh water technologies? |

|

| Drive for sustainable solutions |

| We continuously strive to improve the sustainability of our solutions. To understand the needs of our customers, the requirements of potential and upcoming regulations, and rising global trends, we engage with our stakeholders regularly and in various ways. |

|

| Energy efficiency |

| Our RO desalinators are economical and energy efficient, especially compared to evaporators. If energy recovery systems are used, even higher energy efficiency can be achieved, leading to a shorter amortization time. |

|

| Global lifecycle services |

| We are your global service partner throughout the life cycle of your fresh water solution. Our comprehensive portfolio ranges from long-term service agreements to individual service products such as spare parts, training, maintenance and retrofit. |

|

|

|

|

|

|

|

| What is Evac wastewater treatment? |

Wastewater treatment systems separate and neutralize organic contaminants in wastewater to comply with national and international legislation.

Our offering includes biological and electrolytic wastewater treatment plants that refine black and gray water, as well as grease separators to separate grease from kitchen and galley wastewater. |

|

| How wastewater treatment systems work? |

Our advanced membrane bioreactors (MBRs) and moving bed biofilm reactors (MBBRs) are biological sewage treatment plants. MBBRs are mainly suitable for large cruise vessels, while MBRs are suitable for a wide range of vessels and building facilities, both offshore and on land. Both our MBBRs and MBRs include nutrient removal.

Our comprehensive system offering include also electrolytic wastewater treatment plants, which are especially suitable for naval applications, offshore vessels, and platforms, but they are also used on other vessel types. |

|

| Why choose Evac® wastewater treatment solutions? |

|

| Certified systems |

| Our systems meet the strictest regulations, including IMO MEPC.227 (64), USCG and River Rhine, and can also be operated in Environmentally Sensitive Sea Areas (ESSAs) and Special Areas (SAs). Our wastewater treatment membrane bioreactors can be equipped with nutrient removal module, which allows vessels to operate in Special Areas like the Baltic Sea. |

|

| Customized modular solutions |

| We can provide wastewater treatment solutions for all types of vessels with infinite possibilities. We can deliver systems adapted for limited footprint, difficult spaces, or any other requirements. Also, the modularity of our systems allows us to provide only what you need and take advantage of existing facilities and old units in retrofit cases. |

|

| Robust systems designed by experts |

| With more than 20 years of experience in the field of wastewater treatment for vessels, Evac wastewater systems are proven solutions with long expected lifespan, easy to operate and resistant to operation changes and difficult influents. |

|

|

|

|